SETCO’s anti-corrosion systems offer industry-leading protection against the damaging effects of corrosion, providing an unparalleled defense mechanism that extends the life and productivity of critical infrastructure.

Our innovative approach ensures resilience in harsh environments, protecting assets and enhancing operational safety.

Shields critical components from corrosion.

Reduces maintenance expenses over the system’s life cycle.

Designed with eco-friendly methods.

For over eighteen years, SETCO has proudly served the Egyptian Sugar and Integrated Industries Company, one of Egypt’s largest and most influential industrial enterprises. One of their chemical factories, located in El-Hawamdia, has faced persistent issues with its production unit for over fifty years.

This unit, which is critical for producing solvents like ethyl acetate and butyl acetate, experienced severe erosion in the main reaction column due to the highly reactive materials involved in production. Frequent maintenance, including welding and part replacements, was necessary despite attempts to use more corrosion-resistant metals.

These challenges even prevented the company from producing other valuable products, like diethyl ether, which Egypt must currently import, due to the harsher reactivity of its production materials that no metal could withstand for more than a couple of days.

In 2014, SETCO, in partnership with Mersen France Company, introduced an innovative solution:

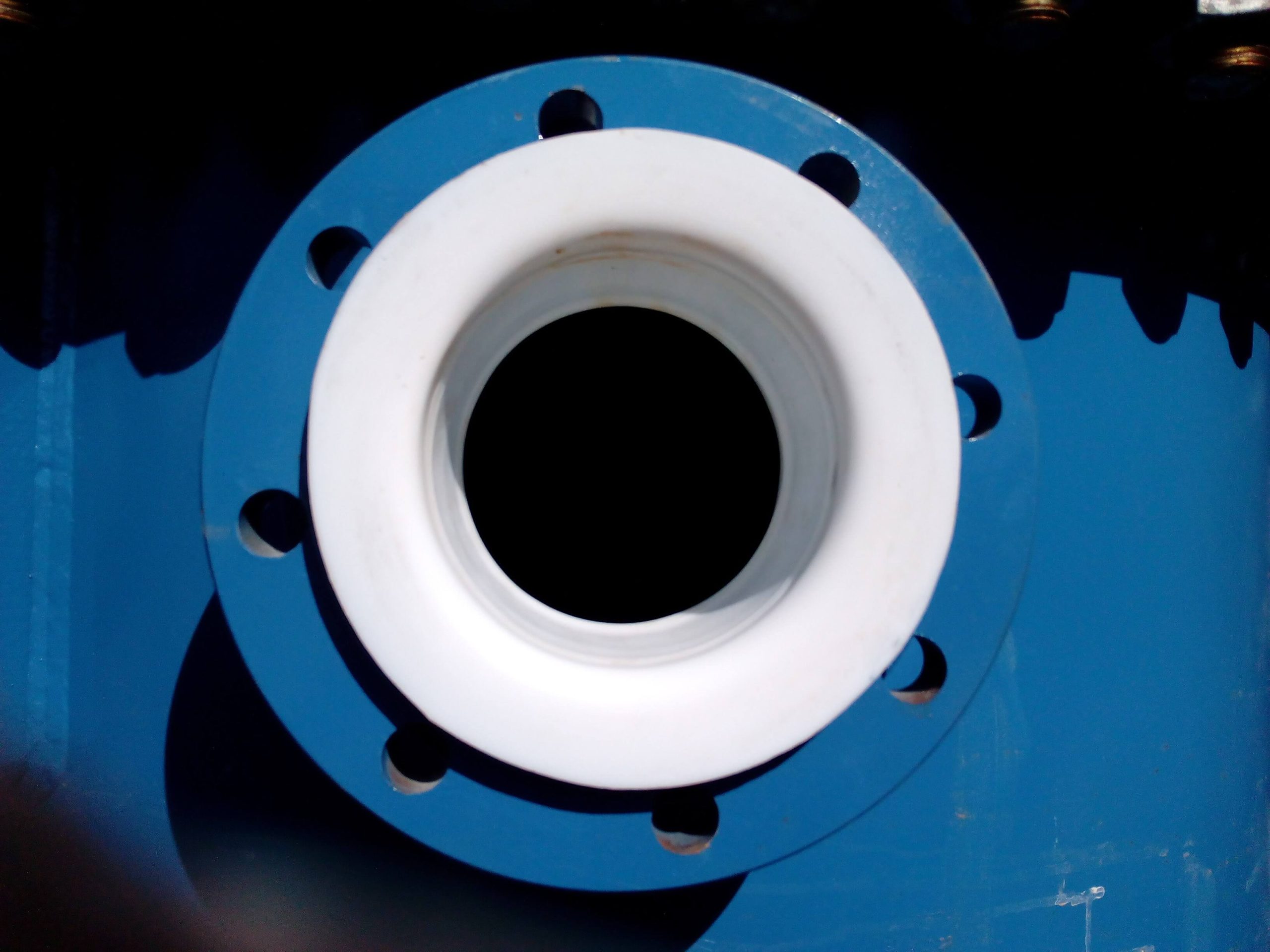

manufacturing the main parts of the reaction column using iron lined with anti-corrosive Teflon. These Teflon-lined components, designed to withstand the aggressive materials involved in production, were produced with large diameters of up to 1200 mm, incorporating reducers, feed holes, various measuring devices, and even a glass liquid level indicator.

By 2015, SETCO had finalized the designs and executive drawings for the primary components of the reaction column. Manufacturing began promptly, and the equipment was supplied, installed, and successfully put into operation the same year.

These parts have been operating efficiently ever since, marking a significant milestone for SETCO and the factory.

The successful completion of this project represented a major technological advancement. For the first time globally, large-scale, complex Teflon-lined parts were specifically manufactured for the Egyptian Sugar and Integrated Industries Company.

With this achievement, the factory could now produce essential solvents that were previously unattainable due to the severe chemical reaction conditions.

In 2016, SETCO proposed an additional enhancement: replacing the feeding line for the main reaction column and the transporter line for the reactive materials.

The new design included pipes, fittings, elbows, and tees made from iron lined with anti-corrosive PTFE/PFA Teflon. This updated feeding line was manufactured, supplied, and installed, effectively ending the operational challenges caused by the old line.

The advanced technology developed by SETCO, in collaboration with Mersen France Company, represents a significant breakthrough for various Egyptian industries facing equipment corrosion challenges.

This solution is especially beneficial for factories producing acids, solvents, salts, fertilizers, paints, and other chemical products, setting a new standard for equipment durability and efficiency.

Copyright 2024 © All Right Reserved | Design by Media Gate.